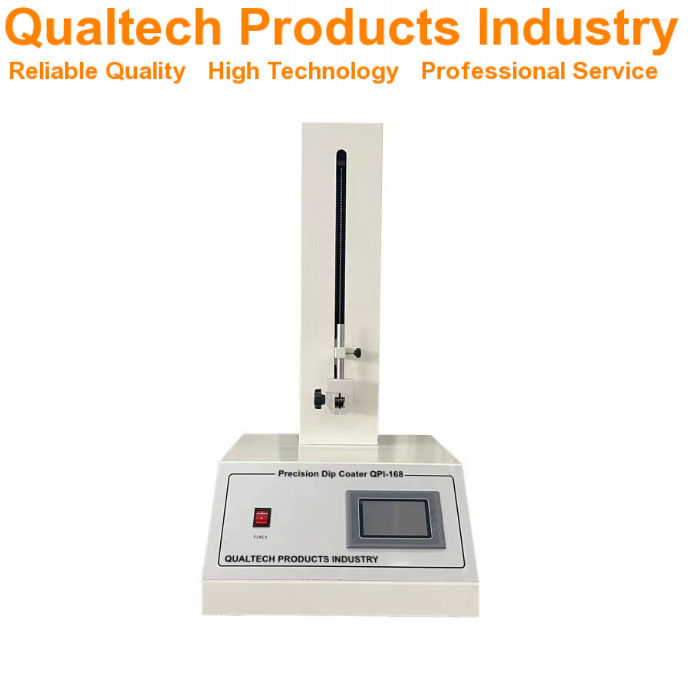

Dip Coating System with Remote Control & Touch Screen Control Panel

For Low Temperature & High Temperature Environments

Model QPI-268

ASTM D823

Product Description:

Qualtech Products Industry professional Dip Coater is a precision Dip Coating System designed for Sol Gel Application and Nanofilm Application at your laboratory for research and quality management.

Dip Coating is an advanced method to create thin nanofilms for research and quality management. Uniform through dip coating created nanofilms can conveniently be applied onto flat or cylindrical samples, including wafers, offering high precision and high repeatability at the touch of a button.

This professional Laboratory Dip Coating System offers the newest microchip technology combined with user-friendly programming features, large Color Touchscreen Display with backlight for comfortable reading under different light conditions, comfortable Softtouch Buttons, a user-friendly menu navigation, an ergonomic design and a reliable performance. In addition this professional Laboratory Dip Coater offers a vibration-free precision motion to ensure precision coating and nano film application.

This precision Dip Coater is engineered for Desktop Application as well as for applications inside a Glove Box, inside a Flow Box and inside a Vacuum Box as well as for applications inside an Environmental Chamber.

This professional Dip Coater is designed and engineered in accordance with international test standards.

The Dip Coating Procedure is usually a method consisting of six main steps:

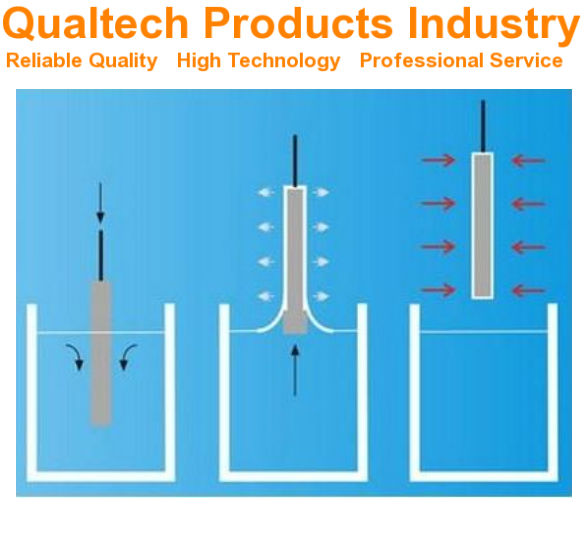

Dip Coating Step 1 – Immersion: The sample is immersed vibration-free and at a constant speed into the coating fluid.

Dip Coating Step 2 – Dwell Time: The sample remains at at preprogrammed position dipped into the coating fluid for a preprogrammed time span.

Dip Coating Step 3 – Withdrawal: The sample has remained inside the solution for a preset time span and is now withdrawn from the coating fluid vibration-free and at a constant speed.

Dip Coating Step 4 – Deposition: The thin nanofilm layer forms on the sample while the sample is moving slowly upwards to its preprogrammed end position. The withdrawal of the sample is performed jitter-free and vibration-free at a constant speed to ensure the required precision motion of the sample. The preset withdrawal speed is one for the relevant factors which determine the thickness of the nanofilm formed on the sample surface.

Dip Coating Step 5 – Drainage: Excessive coating fluid drains from the sample surface.

Dip Coating Step 6 – Evaporation: The solvent evaporates from the coating fluid and forms a thin nanofilm layer on the sample, e.g. wafer. For volatile solvents, e.g. alcohol, the evaporation starts already during the stage of deposition & drainage.

In the continuous process of Dip Coating and Nano Film Application these steps are carried out chronologically. The preprogrammable Coating Counter offers to conveniently preset the number of dip cycles to ensure a convenient and a fully automated dip coating procedure and dip coating experience.

Dip coating methods can be described as a process where the sample to be coated is immersed into a coating liquid and is then withdrawn at a well-defined withdrawal speed under controlled temperature and atmospheric conditions. This precision Dip Coater can be used inside a Glove Box, inside a Vacuum Box and inside an Environmental Chamber (model with Touch Screen & Remote Control). The coating thickness of the nano film applied is mainly defined by the withdrawal speed, by the solid content and the viscosity of the coating fluid.

If reactive systems are chosen for coatings, e.g. Sol-Gel type coatings using alkoxides or pre-hydrolyzed systems (Sols), manging the atmospheric and environmental conditions is indispensable. The atmospheric and environmental conditions influence the evaporation of the solvent and the subsequent destabilization of the Sol through solvent evaporation. This leads to a gelation process and the formation of a transparent film due to the small particle size in the Sol (nm range). This technique is used for dip coating applications to create a two-sided coating when samples or objects show a large and or complex shape.

This Dip Coater with Nano Thin Film Technology adopts the Sol-Gel method to conveniently create Nano Thin Films on samples. Conveniently place a clean and dry sample into the sample holder and this precision Dip Coater will immerse the sample into the coating solution, dwell the sample for a preset time and withdraw the sample from the coating fluid to a preset height and end position. The programmable coating counter is counting the number of immersions and can conveniently be preset for a required number of repeated immersions to best meet your individual test requirements. During this Dip Coating Process a Nano Film is created on the surface of the substrate. The thickness of the Nano Film is determined by the withdrawal speed, the concentration and the viscosity of the coating fluid.

When performing a ‘Sol-Gel Application’ a Nano Film is created on the surface of the sample called “Wet Gel Film”. With the solvent in the Wet Gel Film being volatile the layer on the substrate is solidifies as Dry Gel Film. After the drying and heating treatment the dry gel film will become the desirable nano thin film material.

This Dip Coater is designed and engineered offering a precise, reliable Automatic Dip Coating System which is user-friendly and convenient to use at laboratories under different environmental conditions and it fits well into environmental chambers including fume hoods, glove boxes, magnetic stirrer and laminar airflow benches to ensure a wide range of different applications for research and quality management.

The Dip Coater can easily be modified to operate as an Automatic Dip Coating System producing either single solution coatings or multiple solution coatings by combining the coater with our solution management module (available as accessory).

Dip Coater – Applications:

This precision Automatic Dip Coater is ideal to create and to assist with the evaluation of a wide range of coatings which can be applied on many different sample surfaces including silicon wavers, glass panels, ceramics and different metals.

This Automatic Dip Coater finds its application in many different fields and industries including scientific research, production and quality management, laboratory testing and many more.

Automatic Dip Coater – Features:

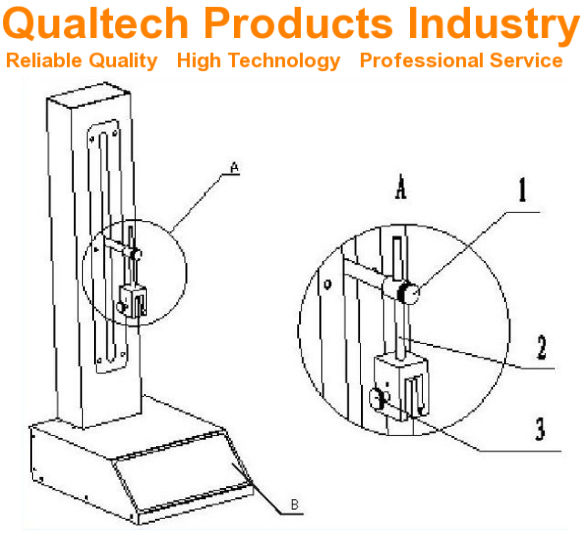

- Newest microchip technology for comfortable and user-friendly programming combined with a vibration-free motion

- Highest precision: 1 µm/min

- Conveniently set the required Speed in the range from 0 – 500 mm/min

- Conveniently program the Immersion (Lowest dip position of the sample, e.g. 0 mm or any value between 0 mm – 300 mm, larger distances are optional available)

- Conveniently program the Withdrawal Height/Length (Top position of the sample, e.g. 300 mm or any value between 0 mm – 300 mm, larger distances are optional available)

- Conveniently program the Immersion Time (Dwell Time)

- Conveniently program the Immersion Counter (How many times the sample shall be immersed into the coating fluid, e.g. once, twice or as many times as 9999)

- Vibration free immersion and withdrawal

- Large Color LCD Digital Display or Large Color Touch Screen for comfortable and easy reading under different light conditions

- Custom Maximum Sample Travel Distances available (Please specify when ordering)

- Custom designed sample holders available to best meet your individual research requirements (Please specify when ordering)

Dip Coating System for Nanofilm Application – Design:

Dip Coater for Nanofilm Application – Specifications:

| Model | QPI-168 |

|---|---|

| Speed Range | 0.000 - 600.000 mm/min conveniently program the required Immersion Speed in mm/min |

| Dwell Time | 1 - 3000 s conveniently set the required Dwell Time in Seconds |

| Coating Counter | 1 - 999 conveniently & automatically count up to thousands of repeated dip procedures |

| Sample Size | Suitable for most sample sizes and sample shapes with custom engineered specimen holders |

| Power | 110 Volts 60 Hz & 220 Volts 50 Hz |

| Newest Design & Future proof | Wide range of custom engineered sample holders available as accessory to best meet your requirements & ideal for possibly changing sample dimensions and sample shapes |

| Newest Microchip Technology | Yes |

| Vibration Damping Design | Yes |

| Precision Engineered | Yes |

| Ergonomic Design & Reliable Performance | Yes |

| Engineered in accordance with international test standards including ASTM D823 | |

Custom engineered Sample Holders ideal for smaller and larger samples and for samples with a complex shape are optional available.

Please see our range of Industrial Scale Dip Coating Systems for industrial scale production lines and production facilities.

Professional Dip Coater – Included items:

- Automatic Dip Coater

- Standard Sample Holder

- Accessories

- Calibration Certificate

- Quality Certificate

- Extended Warranty

- Lifetime Support

- User Manual

Get information now on products, pricing, technical support and professional services.

One of our specialists will reply to your enquiry shortly. Alternatively contact us via the company details in the USA, in Australia or in the UK.